What are the Popular Inductor Magnetic Core Products?

I. Introduction

Inductor magnetic cores are essential components in electrical engineering, playing a crucial role in the design and functionality of inductors. These cores are made from various magnetic materials that enhance the inductance and efficiency of the inductor, allowing it to store energy in a magnetic field when electrical current flows through it. The choice of magnetic core significantly influences the performance characteristics of inductors, including their efficiency, size, and cost. This article aims to explore the different types of inductor magnetic cores, highlight popular products in the market, and discuss the factors influencing their selection and the latest trends in technology.

II. Types of Inductor Magnetic Cores

A. Ferrite Cores

Ferrite cores are made from ceramic compounds that exhibit magnetic properties. They are widely used in high-frequency applications due to their low eddy current losses and high magnetic permeability.

1. **Characteristics and Properties**: Ferrite cores are lightweight, have high electrical resistance, and can operate effectively at high frequencies. They are available in various shapes, including toroidal and E-cores.

2. **Common Applications**: Ferrite cores are commonly used in power supplies, transformers, and RF applications, where efficiency and size are critical.

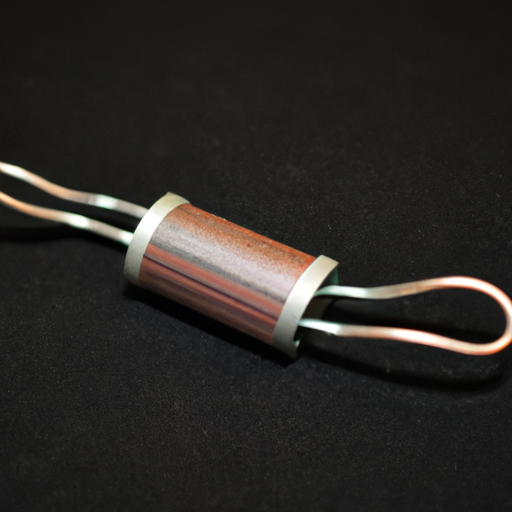

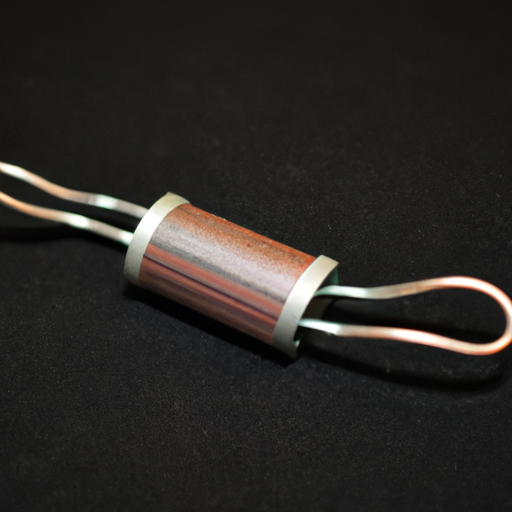

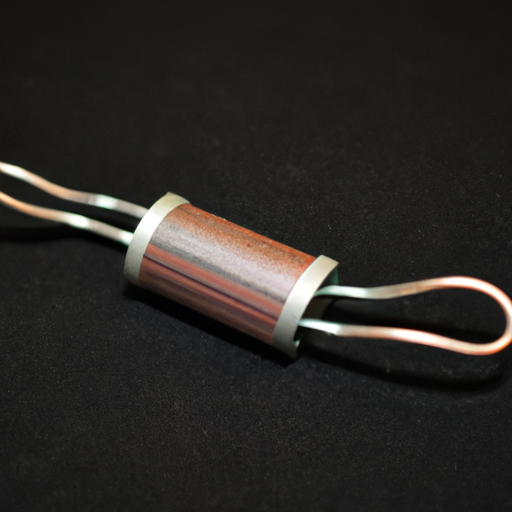

B. Iron Powder Cores

Iron powder cores are made from finely powdered iron particles that are compacted and insulated. They are known for their high saturation flux density.

1. **Characteristics and Properties**: These cores exhibit good magnetic properties and are suitable for low-frequency applications. They can handle higher currents without saturating.

2. **Common Applications**: Iron powder cores are often used in inductors for power electronics, audio equipment, and energy storage applications.

C. Laminated Cores

Laminated cores consist of thin sheets of magnetic material stacked together. This design minimizes eddy current losses, making them suitable for various applications.

1. **Characteristics and Properties**: Laminated cores are robust and can handle high power levels. They are typically made from silicon steel, which enhances their magnetic properties.

2. **Common Applications**: These cores are commonly found in transformers, electric motors, and inductors used in power supplies.

D. Amorphous Cores

Amorphous cores are made from non-crystalline materials, which provide unique magnetic properties. They are known for their low core losses.

1. **Characteristics and Properties**: Amorphous cores have high permeability and low hysteresis losses, making them efficient for high-frequency applications.

2. **Common Applications**: They are used in high-efficiency transformers and inductors, particularly in renewable energy systems and electric vehicles.

E. Composite Cores

Composite cores combine different materials to achieve desired magnetic properties. They can be tailored for specific applications.

1. **Characteristics and Properties**: These cores can offer a balance between cost and performance, making them versatile for various applications.

2. **Common Applications**: Composite cores are used in a range of applications, including power supplies, RF devices, and automotive electronics.

III. Popular Inductor Magnetic Core Products

A. Ferrite Core Products

1. **E-Core Ferrite Inductors**: These inductors are widely used in power supply circuits due to their compact size and efficiency. They are ideal for applications requiring high inductance in a small footprint.

2. **Toroidal Ferrite Inductors**: Known for their low electromagnetic interference (EMI), toroidal ferrite inductors are used in audio equipment and power supplies. Their circular shape allows for efficient magnetic flux containment.

3. **Rod and Pot Cores**: These cores are used in applications where space is limited. They are often found in RF applications and small power supplies.

B. Iron Powder Core Products

1. **Toroidal Iron Powder Inductors**: These inductors are favored for their high current handling capabilities and low losses. They are commonly used in power electronics and audio applications.

2. **C-Core Inductors**: C-core inductors are designed for high-performance applications, providing excellent magnetic properties and efficiency.

C. Laminated Core Products

1. **EI Laminated Cores**: These cores are widely used in transformers and inductors due to their robust design and efficiency in handling high power levels.

2. **U Laminated Cores**: U-shaped laminated cores are often used in applications requiring high inductance and low losses, such as in power transformers.

D. Amorphous Core Products

1. **Amorphous Toroidal Cores**: These cores are known for their low core losses and high efficiency, making them suitable for high-frequency applications.

2. **Amorphous C-Core Inductors**: These inductors provide excellent performance in energy-efficient applications, particularly in renewable energy systems.

E. Composite Core Products

1. **Composite Toroidal Cores**: These cores combine different materials to achieve desired magnetic properties, making them versatile for various applications.

2. **Composite Rod Cores**: Used in applications where space is limited, composite rod cores offer a balance between performance and cost.

IV. Factors Influencing the Choice of Magnetic Cores

When selecting an inductor magnetic core, several factors must be considered:

A. Frequency Response

The frequency at which the inductor operates significantly influences the choice of core material. Ferrite cores are preferred for high-frequency applications, while iron powder cores are better suited for lower frequencies.

B. Saturation Characteristics

The saturation point of a core determines how much current it can handle before losing its inductive properties. Choosing a core with appropriate saturation characteristics is crucial for ensuring reliable performance.

C. Temperature Stability

Temperature variations can affect the performance of magnetic cores. Selecting materials that maintain their magnetic properties across a range of temperatures is essential for consistent operation.

D. Cost Considerations

Cost is always a factor in component selection. While high-performance cores may offer better efficiency, they can also be more expensive. Balancing performance and cost is key to making the right choice.

E. Size and Form Factor

The physical size of the core can impact the overall design of the circuit. Smaller cores may be necessary for compact designs, while larger cores may be required for higher power applications.

V. Trends in Inductor Magnetic Core Technology

A. Advancements in Material Science

Recent advancements in material science have led to the development of new magnetic materials that offer improved performance characteristics, such as lower losses and higher saturation points.

B. Miniaturization of Components

As electronic devices become smaller and more compact, the demand for miniaturized inductors has increased. Manufacturers are developing smaller magnetic cores without compromising performance.

C. Increased Efficiency and Performance

There is a growing emphasis on energy efficiency in electronic devices. New core designs and materials are being developed to minimize energy losses and improve overall performance.

D. Environmental Considerations and Sustainability

With increasing awareness of environmental issues, manufacturers are focusing on sustainable practices, including the use of recyclable materials and energy-efficient production processes.

VI. Conclusion

In summary, inductor magnetic cores are vital components in electrical engineering, influencing the performance and efficiency of inductors. Understanding the different types of magnetic cores, their characteristics, and popular products can help engineers and designers make informed decisions. As technology continues to evolve, advancements in materials and design will shape the future of inductor magnetic core products, leading to more efficient and compact solutions for a wide range of applications.

VII. References

A comprehensive list of references, including academic journals, industry reports, manufacturer specifications, and online resources, can provide further insights into the topic of inductor magnetic cores and their applications.

What are the Popular Inductor Magnetic Core Products?

I. Introduction

Inductor magnetic cores are essential components in electrical engineering, playing a crucial role in the design and functionality of inductors. These cores are made from various magnetic materials that enhance the inductance and efficiency of the inductor, allowing it to store energy in a magnetic field when electrical current flows through it. The choice of magnetic core significantly influences the performance characteristics of inductors, including their efficiency, size, and cost. This article aims to explore the different types of inductor magnetic cores, highlight popular products in the market, and discuss the factors influencing their selection and the latest trends in technology.

II. Types of Inductor Magnetic Cores

A. Ferrite Cores

Ferrite cores are made from ceramic compounds that exhibit magnetic properties. They are widely used in high-frequency applications due to their low eddy current losses and high magnetic permeability.

1. **Characteristics and Properties**: Ferrite cores are lightweight, have high electrical resistance, and can operate effectively at high frequencies. They are available in various shapes, including toroidal and E-cores.

2. **Common Applications**: Ferrite cores are commonly used in power supplies, transformers, and RF applications, where efficiency and size are critical.

B. Iron Powder Cores

Iron powder cores are made from finely powdered iron particles that are compacted and insulated. They are known for their high saturation flux density.

1. **Characteristics and Properties**: These cores exhibit good magnetic properties and are suitable for low-frequency applications. They can handle higher currents without saturating.

2. **Common Applications**: Iron powder cores are often used in inductors for power electronics, audio equipment, and energy storage applications.

C. Laminated Cores

Laminated cores consist of thin sheets of magnetic material stacked together. This design minimizes eddy current losses, making them suitable for various applications.

1. **Characteristics and Properties**: Laminated cores are robust and can handle high power levels. They are typically made from silicon steel, which enhances their magnetic properties.

2. **Common Applications**: These cores are commonly found in transformers, electric motors, and inductors used in power supplies.

D. Amorphous Cores

Amorphous cores are made from non-crystalline materials, which provide unique magnetic properties. They are known for their low core losses.

1. **Characteristics and Properties**: Amorphous cores have high permeability and low hysteresis losses, making them efficient for high-frequency applications.

2. **Common Applications**: They are used in high-efficiency transformers and inductors, particularly in renewable energy systems and electric vehicles.

E. Composite Cores

Composite cores combine different materials to achieve desired magnetic properties. They can be tailored for specific applications.

1. **Characteristics and Properties**: These cores can offer a balance between cost and performance, making them versatile for various applications.

2. **Common Applications**: Composite cores are used in a range of applications, including power supplies, RF devices, and automotive electronics.

III. Popular Inductor Magnetic Core Products

A. Ferrite Core Products

1. **E-Core Ferrite Inductors**: These inductors are widely used in power supply circuits due to their compact size and efficiency. They are ideal for applications requiring high inductance in a small footprint.

2. **Toroidal Ferrite Inductors**: Known for their low electromagnetic interference (EMI), toroidal ferrite inductors are used in audio equipment and power supplies. Their circular shape allows for efficient magnetic flux containment.

3. **Rod and Pot Cores**: These cores are used in applications where space is limited. They are often found in RF applications and small power supplies.

B. Iron Powder Core Products

1. **Toroidal Iron Powder Inductors**: These inductors are favored for their high current handling capabilities and low losses. They are commonly used in power electronics and audio applications.

2. **C-Core Inductors**: C-core inductors are designed for high-performance applications, providing excellent magnetic properties and efficiency.

C. Laminated Core Products

1. **EI Laminated Cores**: These cores are widely used in transformers and inductors due to their robust design and efficiency in handling high power levels.

2. **U Laminated Cores**: U-shaped laminated cores are often used in applications requiring high inductance and low losses, such as in power transformers.

D. Amorphous Core Products

1. **Amorphous Toroidal Cores**: These cores are known for their low core losses and high efficiency, making them suitable for high-frequency applications.

2. **Amorphous C-Core Inductors**: These inductors provide excellent performance in energy-efficient applications, particularly in renewable energy systems.

E. Composite Core Products

1. **Composite Toroidal Cores**: These cores combine different materials to achieve desired magnetic properties, making them versatile for various applications.

2. **Composite Rod Cores**: Used in applications where space is limited, composite rod cores offer a balance between performance and cost.

IV. Factors Influencing the Choice of Magnetic Cores

When selecting an inductor magnetic core, several factors must be considered:

A. Frequency Response

The frequency at which the inductor operates significantly influences the choice of core material. Ferrite cores are preferred for high-frequency applications, while iron powder cores are better suited for lower frequencies.

B. Saturation Characteristics

The saturation point of a core determines how much current it can handle before losing its inductive properties. Choosing a core with appropriate saturation characteristics is crucial for ensuring reliable performance.

C. Temperature Stability

Temperature variations can affect the performance of magnetic cores. Selecting materials that maintain their magnetic properties across a range of temperatures is essential for consistent operation.

D. Cost Considerations

Cost is always a factor in component selection. While high-performance cores may offer better efficiency, they can also be more expensive. Balancing performance and cost is key to making the right choice.

E. Size and Form Factor

The physical size of the core can impact the overall design of the circuit. Smaller cores may be necessary for compact designs, while larger cores may be required for higher power applications.

V. Trends in Inductor Magnetic Core Technology

A. Advancements in Material Science

Recent advancements in material science have led to the development of new magnetic materials that offer improved performance characteristics, such as lower losses and higher saturation points.

B. Miniaturization of Components

As electronic devices become smaller and more compact, the demand for miniaturized inductors has increased. Manufacturers are developing smaller magnetic cores without compromising performance.

C. Increased Efficiency and Performance

There is a growing emphasis on energy efficiency in electronic devices. New core designs and materials are being developed to minimize energy losses and improve overall performance.

D. Environmental Considerations and Sustainability

With increasing awareness of environmental issues, manufacturers are focusing on sustainable practices, including the use of recyclable materials and energy-efficient production processes.

VI. Conclusion

In summary, inductor magnetic cores are vital components in electrical engineering, influencing the performance and efficiency of inductors. Understanding the different types of magnetic cores, their characteristics, and popular products can help engineers and designers make informed decisions. As technology continues to evolve, advancements in materials and design will shape the future of inductor magnetic core products, leading to more efficient and compact solutions for a wide range of applications.

VII. References

A comprehensive list of references, including academic journals, industry reports, manufacturer specifications, and online resources, can provide further insights into the topic of inductor magnetic cores and their applications.