Application Development in NTC Thermistors for ECS-F1VE155K: Key Technologies and Success StoriesNTC (Negative Temperature Coefficient) thermistors, such as the ECS-F1VE155K, are essential components in a wide range of electronic applications due to their sensitivity to temperature changes. Their unique characteristics make them suitable for various industries, including automotive, consumer electronics, HVAC, medical devices, and IoT. Below, we explore key technologies and notable success stories that highlight the application development of NTC thermistors.

Key Technologies1. Temperature Sensing and Compensation2. Automotive Applications3. Consumer Electronics4. HVAC Systems5. Medical Devices6. Internet of Things (IoT)1. Electric Vehicle Battery Management2. Smart Thermostats3. Medical Monitoring Devices4. HVAC Control Systems5. Consumer Electronics Thermal Management Success Stories ConclusionThe ECS-F1VE155K NTC thermistor exemplifies the versatility and effectiveness of NTC thermistors across various applications. As technology advances and the demand for precise temperature control continues to grow, the role of NTC thermistors in modern electronic systems is expected to expand further. This will likely lead to more innovative applications and success stories, reinforcing the importance of NTC thermistors in enhancing safety, efficiency, and performance across multiple industries.

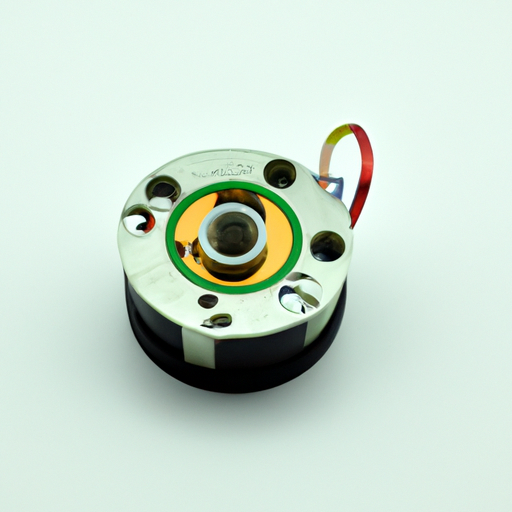

Certainly! Encoders are pivotal components in automation, robotics, and motion control, converting physical motion into electrical signals for precise control and feedback. Below is a detailed overview of core functional technologies, insightful articles, and practical application development cases related to encoders, particularly focusing on the IRF510 and similar technologies.

Core Functional Technologies of Encoders1. Types of Encoders2. Signal Processing3. Communication Protocols4. Resolution and Accuracy5. Environmental Considerations1. "Understanding the Basics of Rotary Encoders"2. "Choosing the Right Encoder for Your Application"3. "The Role of Encoders in Motion Control Systems"4. "Advancements in Encoder Technology"1. Robotics2. CNC Machining3. Automated Guided Vehicles (AGVs)4. Industrial Automation5. Medical Devices Articles on Encoder Technology Application Development Cases ConclusionEncoders are integral to modern automation and control systems, providing essential feedback for precise motion control. Understanding their core technologies, selecting the appropriate type for specific applications, and leveraging real-world case studies can significantly enhance engineering solutions. As technology continues to advance, the integration of encoders with IoT and smart systems will further evolve, opening new avenues for innovation across various industries.

Core Functional Technology of IGBT Modules1. Structure and Operation2. Switching Characteristics3. Thermal Management4. Gate Drive Requirements5. Protection Features1. Renewable Energy Systems2. Electric Vehicles (EVs)3. Industrial Drives4. HVDC Transmission5. Power Supplies Application Development Cases ConclusionIGBT modules are pivotal in modern power electronics, providing efficient and reliable solutions across a wide range of applications. Their unique combination of high voltage and current handling capabilities, along with fast switching speeds, makes them suitable for renewable energy systems, electric vehicles, industrial drives, HVDC transmission, and power supplies. As technology continues to advance, the development of IGBT modules is expected to evolve further, leading to even more efficient, compact, and reliable designs that meet the growing demands of various industries.

ECS-F1VE685K Zener Diode Arrays: Core Functional Technologies and Application Development CasesZener diode arrays, such as the ECS-F1VE685K, are integral components in electronic circuits, providing essential functions like voltage regulation, overvoltage protection, and signal conditioning. Below, we delve into the core functional technologies and application development cases that showcase the effectiveness of Zener diode arrays.

Core Functional Technologies1. Voltage Regulation2. Overvoltage Protection3. Signal Clamping4. Temperature Stability5. Compact Design1. Power Supply Circuits2. Transient Voltage Suppression3. Data Line Protection4. LED Driver Circuits5. Battery Management Systems6. Consumer Electronics Application Development Cases ConclusionZener diode arrays, exemplified by the ECS-F1VE685K, are crucial in modern electronic design, providing essential functions such as voltage regulation, overvoltage protection, and signal integrity. Their versatility and effectiveness make them suitable for a wide array of applications, from power supplies to automotive electronics and consumer devices. As technology advances, the demand for reliable and compact Zener diode solutions will continue to grow, driving further innovation in this essential field.

Application Development in Single, Pre-Biased Bipolar TransistorsThe use of single, pre-biased bipolar transistors has become increasingly important in various electronic applications due to their ability to enhance performance, reduce distortion, and improve overall circuit efficiency. Below, we explore key technologies and notable success stories that highlight the impact of these transistors across different industries.

Key Technologies in Single, Pre-Biased Bipolar Transistors1. Pre-Biasing Techniques2. Integrated Circuit Design3. Thermal Management4. Simulation and Modeling5. Packaging Technologies1. Consumer Electronics2. Telecommunications3. Automotive Applications4. Medical Devices5. Industrial Automation Success Stories ConclusionThe application development of single, pre-biased bipolar transistors has significantly influenced various industries, enhancing the performance and reliability of electronic devices. As technology continues to advance, the integration of these transistors into more sophisticated systems will likely drive further innovations, leading to new success stories across sectors such as consumer electronics, telecommunications, automotive, medical devices, and industrial automation. The ongoing evolution of design techniques, thermal management, and packaging technologies will continue to support the growth and application of bipolar transistors in the future.

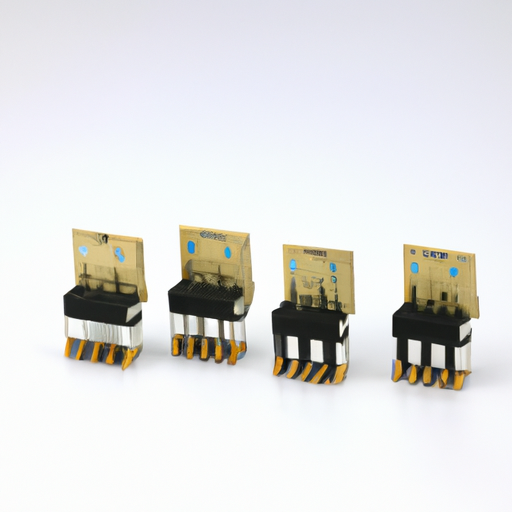

CFR-50JB-52-1M8 Bipolar Transistor Arrays: Core Functional Technology and Application DevelopmentBipolar transistor arrays, such as the CFR-50JB-52-1M8, are integral components in modern electronics, providing versatile solutions for a wide range of applications. This document highlights the core functional technology behind bipolar transistor arrays and presents several application development cases that demonstrate their effectiveness.

Core Functional Technology Articles1. Understanding Bipolar Transistor Arrays2. Advantages of Using Bipolar Transistor Arrays3. Applications of Bipolar Transistor Arrays1. LED Driver Circuits2. Motor Control3. Signal Conditioning in Sensors4. Audio Amplification Application Development Cases ConclusionBipolar transistor arrays, exemplified by the CFR-50JB-52-1M8, offer significant advantages in terms of space efficiency, performance, and cost-effectiveness across various electronic applications. By understanding their core technology and exploring practical application cases, engineers can design more efficient and effective electronic systems. As technology continues to advance, the role of bipolar transistor arrays in modern electronics is expected to expand, solidifying their importance in future designs.

Application Development in Single Bipolar Transistors for CFR-25JB-52-1K8: Key Technologies and Success StoriesThe CFR-25JB-52-1K8 is a precision resistor that can be utilized in various electronic circuits, including those that employ single bipolar transistors (BJTs). While the resistor itself is not directly related to BJTs, it plays a crucial role in circuit design, particularly in biasing, feedback, and signal conditioning applications. Below, we explore key technologies associated with single bipolar transistors and highlight success stories that illustrate their application in conjunction with resistors like the CFR-25JB-52-1K8.

Key Technologies in Single Bipolar Transistor Applications1. Signal Amplification2. Switching Circuits3. Oscillator Circuits4. Linear Voltage Regulation5. Current Mirrors6. Feedback and Control Systems1. High-Fidelity Audio Amplifiers2. AM/FM Radio Transmitters3. Power Management ICs4. Sensor Signal Conditioning5. Telecommunications Equipment Success Stories ConclusionSingle bipolar transistors are fundamental components in a wide range of electronic applications, from audio amplification to power management. Their versatility in amplification and switching, combined with the precision of resistors like the CFR-25JB-52-1K8, leads to enhanced performance and reliability in circuit designs. As technology continues to advance, the integration of BJTs with modern digital components and precision resistors will foster innovative applications and improved performance in electronic systems. The collaboration between BJTs and resistors exemplifies the importance of component synergy in achieving optimal circuit functionality.

Application Development in Special Purpose for LT1178ACN8: Key Technologies and Success StoriesThe LT1178ACN8, a precision voltage reference and operational amplifier from Analog Devices, is renowned for its high accuracy and low noise characteristics. This makes it a preferred choice in various specialized applications. Below, we explore the key technologies that leverage the capabilities of the LT1178ACN8 and highlight notable success stories across different sectors.

Key Technologies1. Precision Analog Design2. Low Noise Amplification3. Integrated Circuit Design4. Temperature Compensation5. Feedback and Control Systems1. Medical Instrumentation2. Industrial Automation3. Consumer Electronics4. Data Acquisition Systems5. Automotive Applications Success Stories ConclusionThe LT1178ACN8 stands out as a versatile component that has enabled numerous successful applications across various industries. Its precision, low noise, and reliability make it an excellent choice for special-purpose applications in medical, industrial, consumer electronics, and automotive sectors. As technology continues to advance, the LT1178ACN8 is poised to remain a key player in the development of sophisticated electronic systems, driving innovation and enhancing performance across diverse applications.

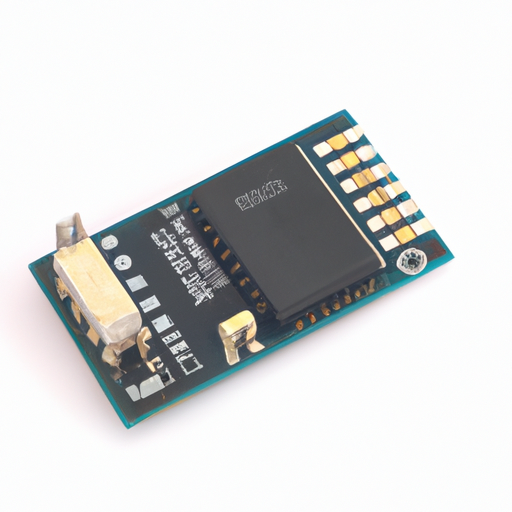

Overview of CFR-50JB-52-10K IGBT ArraysThe CFR-50JB-52-10K IGBT Array is a specialized component in the realm of power electronics, designed to facilitate efficient switching and control of electrical power across various applications. As a type of Insulated Gate Bipolar Transistor (IGBT), it combines the advantages of both MOSFETs and bipolar transistors, making it ideal for high-power applications. Below, we delve into the core functional technologies and application development cases that highlight the effectiveness of IGBT arrays, particularly the CFR-50JB-52-10K.

Core Functional Technologies of IGBT Arrays1. High Efficiency and Low Switching Losses2. Thermal Management3. Integrated Protection Features4. Modular Design5. Gate Drive Optimization1. Renewable Energy Systems2. Electric Vehicles (EVs)3. Industrial Motor Drives4. Power Supply Systems5. HVAC Systems Application Development Cases ConclusionThe CFR-50JB-52-10K IGBT Array represents a significant advancement in IGBT technology, offering high efficiency, integrated protection features, and a modular design that is suitable for a diverse range of applications. Its deployment in renewable energy systems, electric vehicles, industrial motor drives, power supply systems, and HVAC applications underscores the versatility and effectiveness of IGBT arrays in modern power electronics. As technology continues to advance, IGBT arrays like the CFR-50JB-52-10K will play an increasingly vital role in enabling efficient and sustainable energy solutions, driving innovation across various industries.

Overview of ECQ-P1H333GZ Single Zener DiodesThe ECQ-P1H333GZ is a specific model of a single Zener diode, a semiconductor device that allows current to flow in the reverse direction when a specific voltage, known as the Zener voltage, is reached. Zener diodes are widely utilized in various applications, including voltage regulation, protection circuits, and signal clipping, making them essential components in modern electronic design.

Core Functional Technology1. Voltage Regulation 2. Reverse Breakdown Mechanism 3. Temperature Stability 4. Low Noise Operation 5. Power Dissipation 1. Power Supply Regulation2. Overvoltage Protection3. Signal Clipping4. Reference Voltage Generation5. LED Protection Application Development Cases ConclusionThe ECQ-P1H333GZ single Zener diode is a versatile and critical component in a wide range of electronic applications. Its capabilities in voltage regulation, overvoltage protection, and stable reference voltage generation make it indispensable in modern electronic design. By understanding its core functionalities and exploring various application cases, engineers can effectively integrate Zener diodes into their projects, enhancing both performance and reliability.

Application Development in Diode Arrays for 2474-26L: Key Technologies and Success StoriesDiode arrays, particularly the 2474-26L model, have emerged as pivotal components in a variety of applications due to their efficiency, compactness, and versatility. Below, we explore the key technologies that underpin these diode arrays and highlight notable success stories that illustrate their impact across different sectors.

Key Technologies1. High-Efficiency Diodes 2. Thermal Management 3. Modular Design 4. Advanced Packaging 5. Control Systems 6. Smart Integration 1. Medical Imaging 2. Industrial Automation 3. Consumer Electronics 4. Telecommunications 5. Agricultural Technology 6. Automotive Applications Success Stories ConclusionThe development of diode arrays, particularly models like the 2474-26L, has led to significant advancements across various industries. By leveraging key technologies such as high efficiency, effective thermal management, and smart integration, these diode arrays have enabled innovative solutions that enhance performance, reduce costs, and promote sustainability. The success stories across medical, industrial, consumer, telecommunications, agricultural, and automotive sectors underscore the versatility and transformative impact of diode arrays in modern technology. As industries continue to evolve, the role of diode arrays is likely to expand, driving further innovation and efficiency.

Application Development in RF Diodes for CFR-25JB-52-100K: Key Technologies and Success StoriesThe development of RF diodes, particularly the CFR-25JB-52-100K, is pivotal in enhancing performance across various applications, including telecommunications, broadcasting, and radar systems. Below, we delve into the key technologies that underpin these advancements and highlight notable success stories that illustrate their impact.

Key Technologies1. High-Frequency Performance2. Low Noise Figure (NF)3. Power Handling4. Tuning and Matching Networks5. Integration with MMICs6. Advanced Materials7. Digital Signal Processing (DSP)1. Telecommunications2. Broadcasting3. Radar Systems4. Consumer Electronics5. Medical Applications Success Stories ConclusionThe development of RF diodes, exemplified by the CFR-25JB-52-100K, is driven by continuous advancements in materials, design methodologies, and integration with other technologies. The success stories across diverse industries underscore the critical role of RF diodes in enhancing communication, broadcasting, and radar systems. As applications evolve, ongoing research and development will further expand the capabilities and performance of RF diodes, solidifying their importance in modern technology.

Application Development in Variable Capacitance (Varicaps, Varactors) for MM74HC245AN: Key Technologies and Success StoriesVariable capacitance devices, commonly known as varicaps or varactors, are semiconductor diodes that utilize the voltage-dependent capacitance of a reverse-biased p-n junction. These devices are essential in various applications, particularly in RF and analog circuits, due to their ability to tune frequency and filter signals. The MM74HC245AN is an octal bus transceiver that can be effectively used alongside varactors in numerous application scenarios. Below are some key technologies and success stories related to the application development of varicaps in conjunction with the MM74HC245AN.

Key Technologies1. Tuning Circuits2. Filters3. RF Applications4. Signal Processing5. Communication Systems1. Telecommunications2. Consumer Electronics3. Automotive Applications4. Medical Devices5. Research and Development Success Stories ConclusionThe combination of variable capacitance devices and the MM74HC245AN has led to significant advancements across various fields, including telecommunications, consumer electronics, automotive systems, and medical devices. The ability to dynamically tune circuits and manage data flow effectively has opened up new possibilities for innovation and improved performance in electronic systems. As technology continues to evolve, the integration of varactors and bus transceivers like the MM74HC245AN will likely play a crucial role in the development of next-generation applications, driving further advancements in electronic design and functionality.

Overview of CFR-50JB-52-100R SCRsThe CFR-50JB-52-100R is a specific model of Silicon Controlled Rectifier (SCR) that exemplifies the capabilities of SCR technology in power control applications. SCRs are semiconductor devices that can handle high voltages and currents, making them essential in various industrial and consumer applications. Below, we delve into the core functional technology articles and application development cases that highlight the effectiveness of SCRs, particularly the CFR-50JB-52-100R.

Core Functional Technology Articles1. Introduction to SCRs:2. Operation Principles:3. Comparison with Other Devices:4. Thermal Management:5. Gate Triggering Techniques:1. Motor Control:2. Phase Control in Lighting:3. Power Supplies:4. Heating Applications:5. Renewable Energy Systems:6. Overvoltage Protection: Application Development Cases ConclusionThe CFR-50JB-52-100R SCR exemplifies the versatility and effectiveness of SCR technology in modern electronic applications. By understanding the core functional technologies and application cases, engineers and designers can leverage SCRs to enhance performance, efficiency, and reliability in various systems. As technology continues to advance, SCRs are expected to find new applications in emerging fields such as electric vehicles, smart grids, and advanced industrial automation, further solidifying their importance in power control and management.

Application Development in Single Diodes for MM74HC251N: Key Technologies and Success StoriesThe MM74HC251N is a high-speed CMOS 8-channel multiplexer/demultiplexer that plays a crucial role in various applications, including data routing, signal switching, and digital signal processing. Integrating single diodes into circuits utilizing the MM74HC251N can significantly enhance performance and reliability. Below, we explore key technologies and notable success stories in this domain.

Key Technologies1. Signal Conditioning2. Switching Applications3. Power Management4. Data Communication1. Consumer Electronics2. Industrial Automation3. Telecommunications4. Automotive Applications Success Stories ConclusionIntegrating single diodes with the MM74HC251N enhances the performance and reliability of various applications, spanning consumer electronics, industrial automation, telecommunications, and automotive systems. By leveraging the protective and signal conditioning capabilities of diodes, developers can create robust systems that meet the demands of modern technology. As technology continues to evolve, the combination of these components will likely lead to even more innovative applications and success stories, paving the way for advancements in circuit design and functionality.